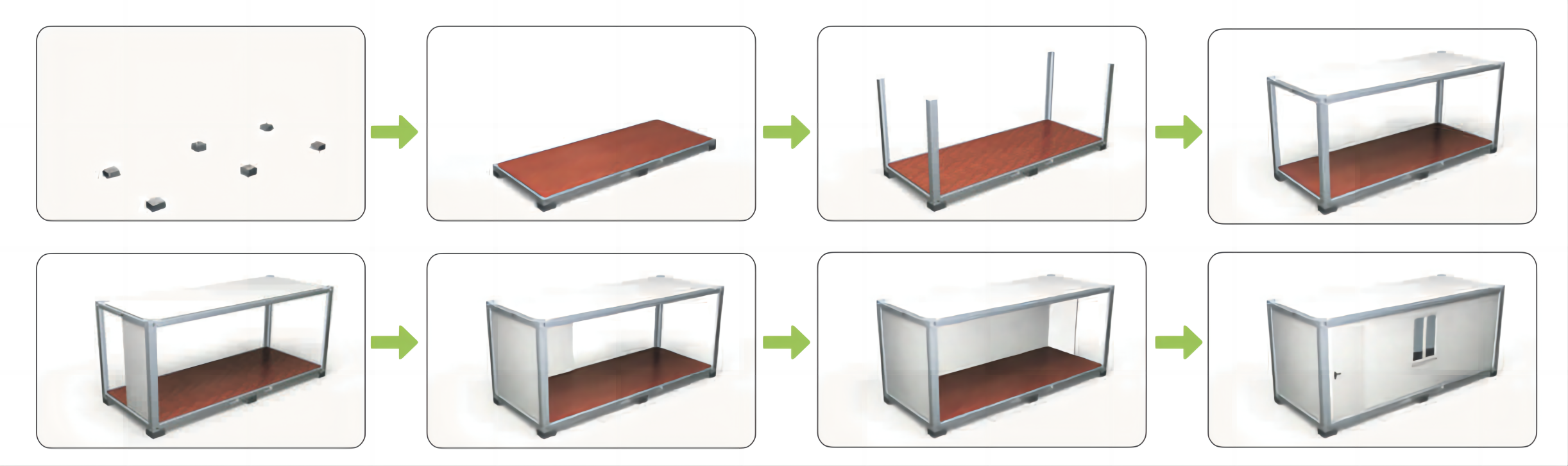

Full-process Solution for Assembling

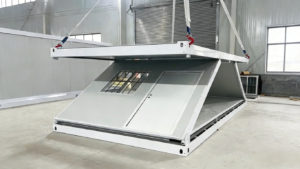

Detached container houses feature fast on-site splicing with standardized components. Installation takes only 4–8 hours per unit, requiring simple tools and minimal labor. The process includes foundation leveling, frame fastening, wall/roof assembly, and interior fitting, with waterproof sealing strips for weather resistance.

For precautions, ensure the ground bears sufficient load and the structure stays level. Reinforce multi-story units with steel supports, and conduct waterproof and safety checks post-installation. Avoid construction in harsh weather to prevent rust and structural defects.