Process for Assembling

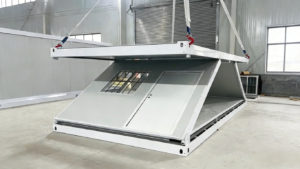

Installation starts with preparing a flat, firm site. Unfasten the folded unit, lift the roof to unfold walls automatically, then lock them with pins and bolts. Assemble accessories like doors, windows and utilities, and conduct a final check.

Key precautions: avoid harsh weather; ensure personnel wear protective gear; fasten all connectors tightly; seal gaps between combined units; store and transport the folded unit properly to prevent damage.