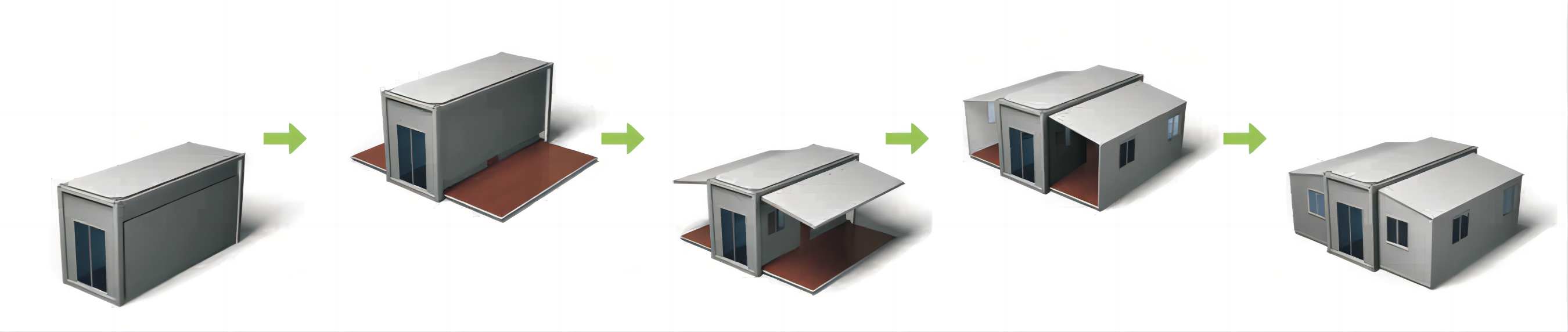

Process for Installation

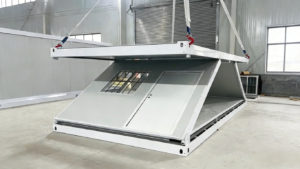

To install, first level the site, hoist the folded unit into position, remove transport locks, then slowly extend and lock both wings. Adjust and secure the support legs, reinforce the connecting hinges, hook up pre-installed utilities, and check structural stability before use—all taking just hours. Key precautions include keeping the unit strictly level during setup, operating wing extension steadily to prevent hinge damage, anchoring the base with expansion bolts in windy areas or for long-term use, and following manufacturer guidance for first-time installation to ensure safety and durability.